Augmented Reality

Innovative solution for space planning

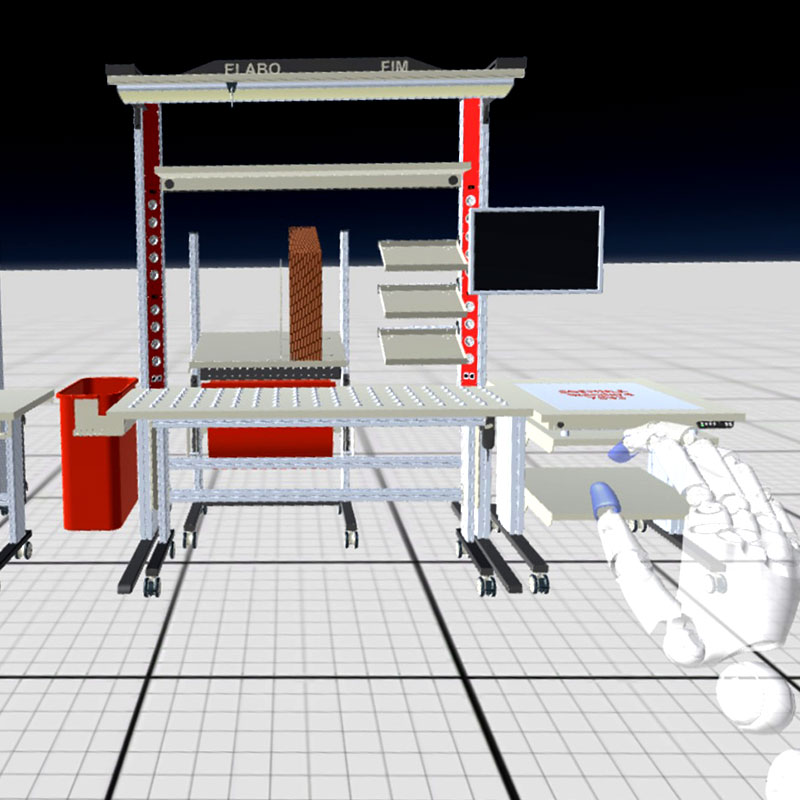

With our Augmented Reality application we offer you the possibility of configuring our workstation solutions and experiencing them live.

How does that work?

The Augmented Reality Sales Configurator developed together with TruPhysics is simple to use and can easily be operated via tablet PC. Rather than falling back on classic sales documents, the workstation solutions can be experienced this way. Workstations can be configured digitally and added to the required environment. This allows you to plan additions to existing equipment or hide an already furnished environment completely. This last option is made possible by an “empty room” functionality.

Advantages

Clear added value, because our workstation solutions can be visualised impressively realistically and be inspectey you in advance. A 3D-based configuration process reduces complexity and avoids plausibility errors. On the basis of the configuration prepared on site, detailed offers can be drawn up for tailor-made solutions without any time delay. The AR application makes the communication process between supplier and customer easier and faster.