Take advantage of the potential of connected production

The new technology of Industry 4.0 offers numerous possibilities for the horizontal and vertical connection of your manufacturing processes. Network-capable devices, logistics or robot system can be integrated according to their application. Thus, processes are matched individually to your needs.

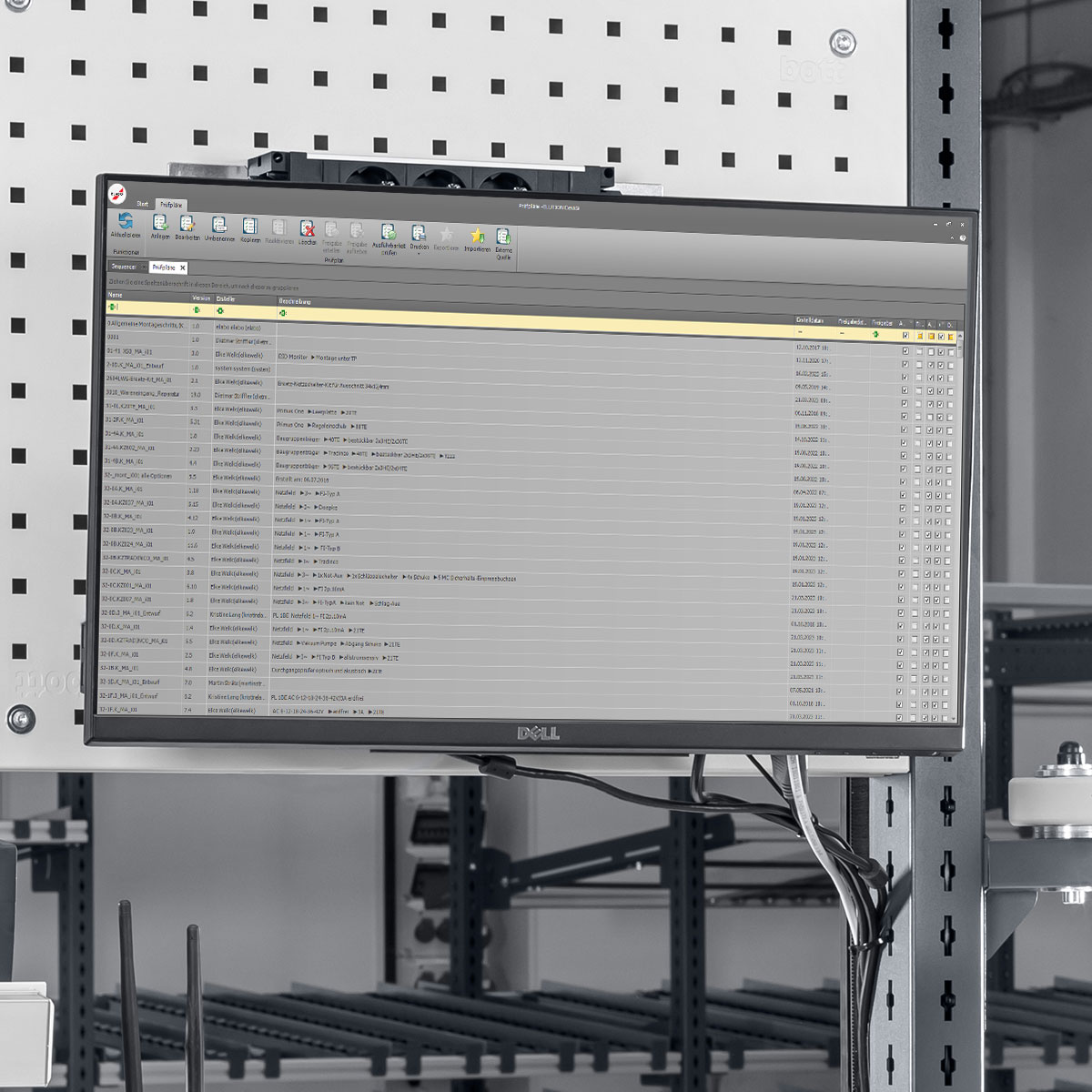

You achieve full potential by integrating elution in your IT landscape. Your ERP controls efficient order processing and all the data or reports that incur on the shopfloor can be transferred and saved in your enterprise resource planning.

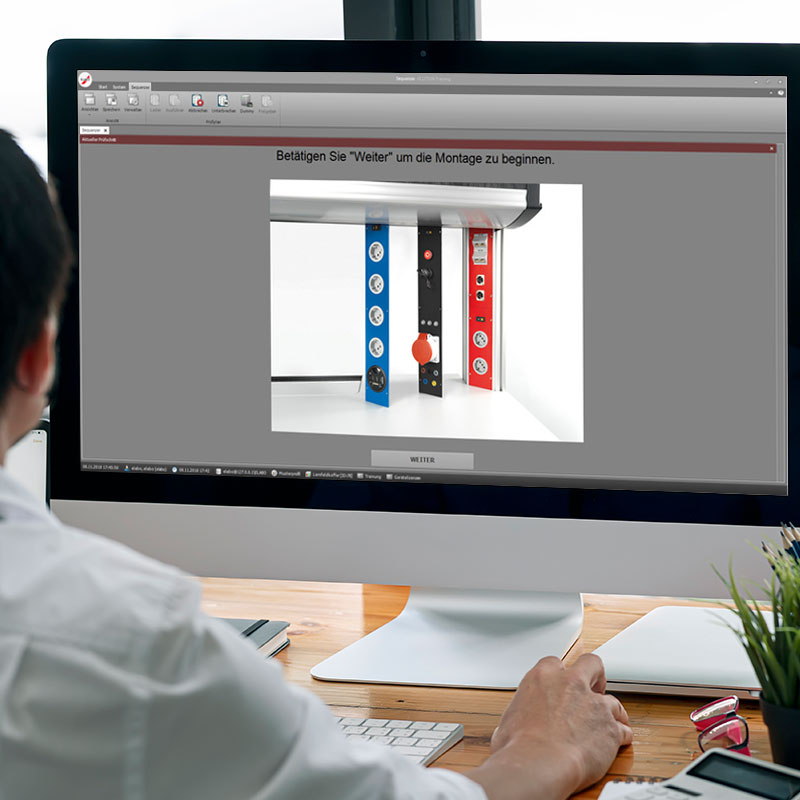

Partial automation is state-of-the-art in numerous assembly processes and offers numerous advantages. Systems such as WiFi screwdrivers, camera systems, measuring devices and much more can be actuated directly in order to automate error-prone, complex or even just very repetitive activities.