Fully automatic testing

Fully automatic testing of the dielectric strength, protective conductor connection and power measurement of built-in refrigerators

Our components

- Protective conductor testing

- High-voltage testing

- Power measurement

- Central SQL database

- Automatic contacting modules

- Connection to the customer's BDE control system

- Automated positioning of test adapters

- Rationalisation of the test sequence

- One test base station for all product groups

- Automatic adaptation to product sizes

- Automatic contacting

- RFID / 2D barcode test data recognition

Project description

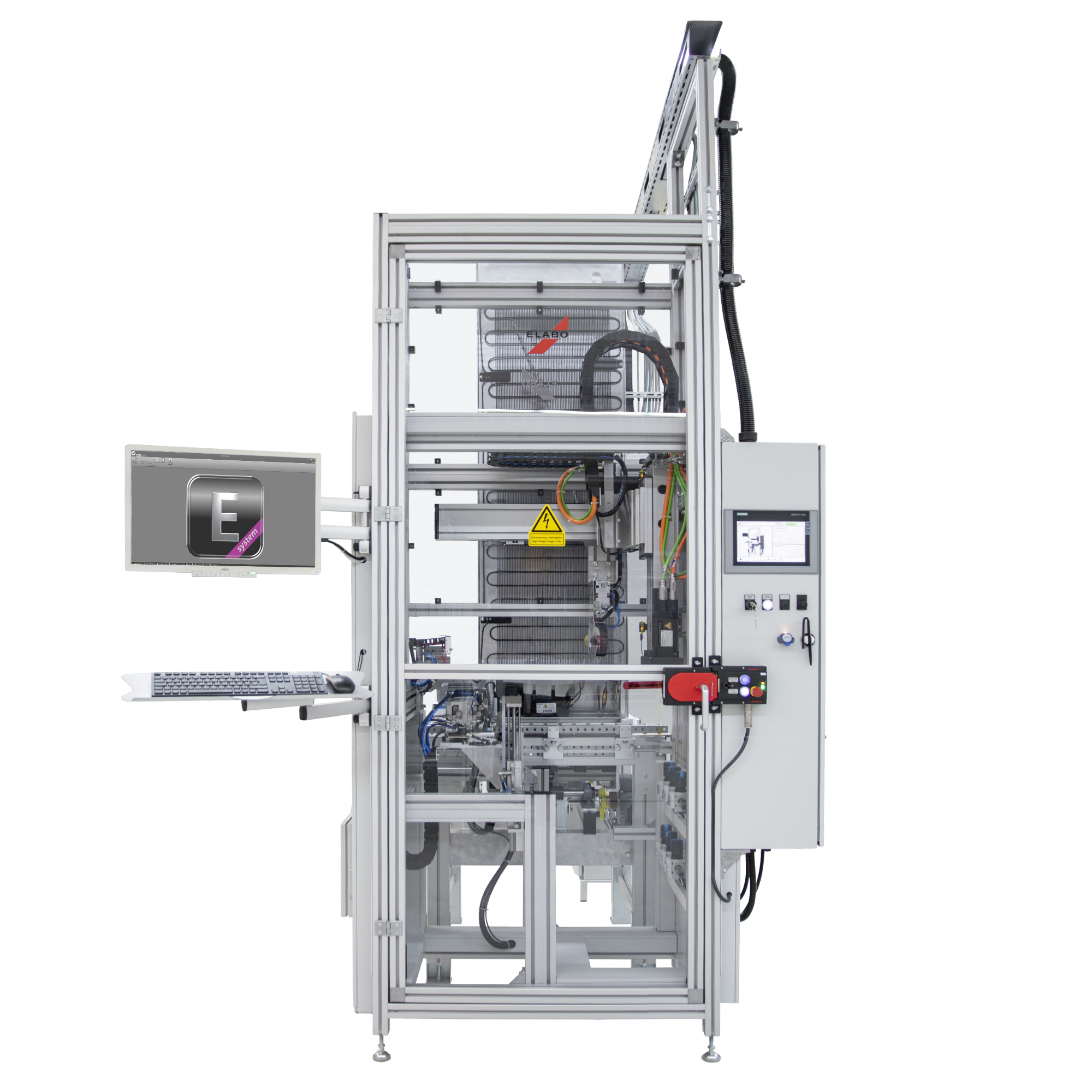

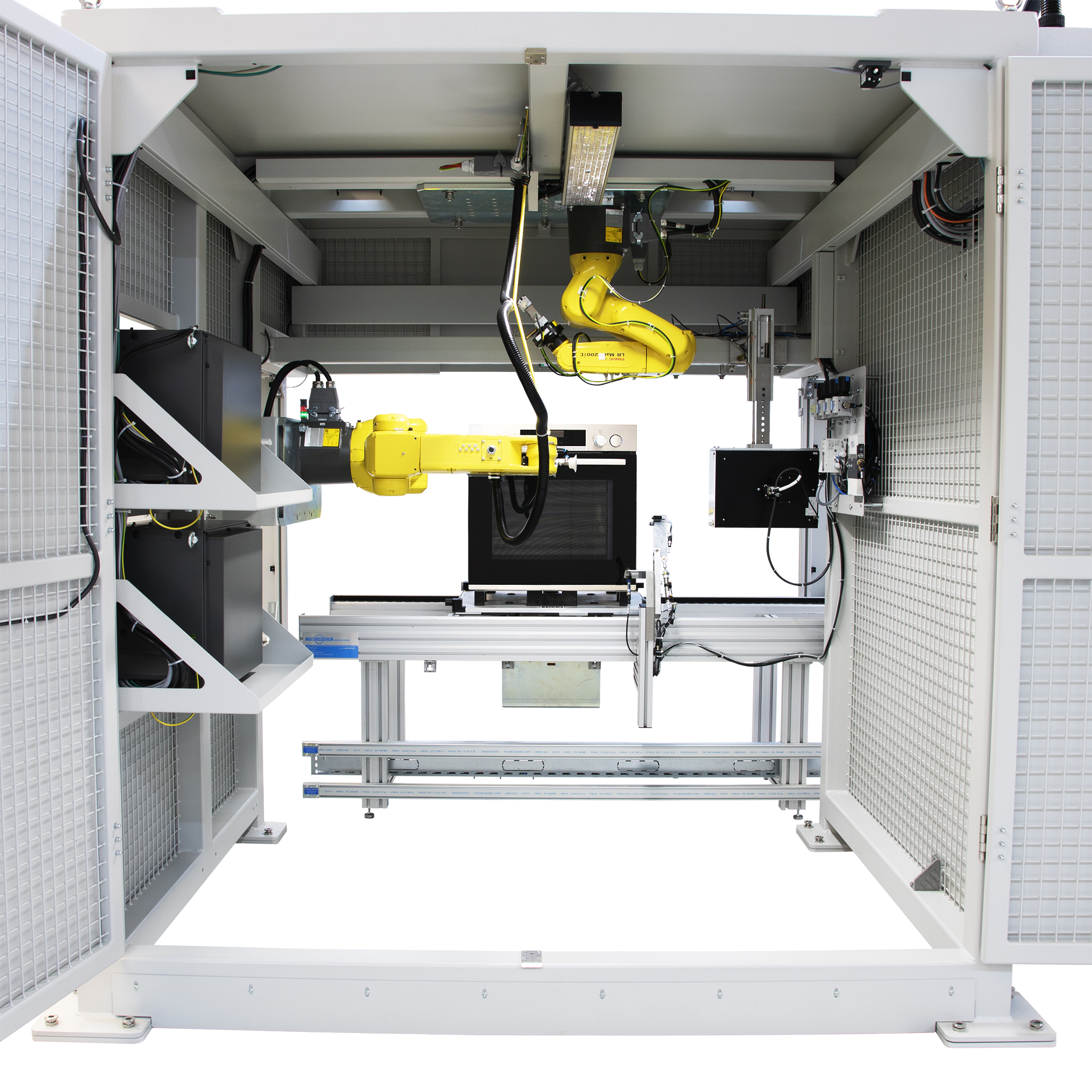

The test system automatically checks the dielectric strength (HV), the protective conductor resistance (PE) and the power consumption of the consumers in the refrigerators. The appliances to be tested are transported to the test position on pallets via a conveyor system and placed and fixed there using a pneumatic device. The conveyor system reports "appliances in position" to the ELABO test system via a digital interface and scans the type code (appliance barcode) of the appliance to be tested. The type data is reported to the BDE control system. The customer's PDA system transfers the relevant test data to the elution software for device-specific testing. Automatic device contacting (mains contacting and PE contacting) is carried out in the test portal using the axis system. Once the test has been completed, the test data is automatically reported back to the PDA system. The system rack contains all measuring devices, the system PC, the connection and switching of test voltages and test currents, as well as the control of automatic contacting for mains contacting and PE test adapters.